Dé reparatiespecialist in Apple reparaties - ook voor Android en PC

iRepairNow is dé reparatiespecialist voor iPhones, iPads, MacBooks en iMac computers. Daarnaast kun je bij ons terecht voor een breed scala aan mobiele accessoires en gereviseerde of refurbished apparaten. Na vele verzoeken van onze klanten, richten we ons nu ook op de Android- en Windows-markt, omdat de verschillende systemen steeds beter op elkaar aansluiten. Kom dus maar op met die Samsung!

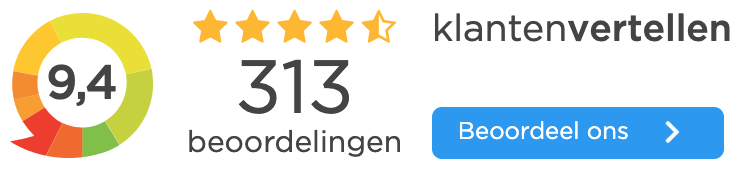

Sinds de succesvolle lancering in 2012, groeide iRepairNow uit tot een bekend reparatiebedrijf in Haarlem en ver daarbuiten. We hebben een zeer grote klantenkring en zijn trots op onze snelle reparatieservice. Onze iRepairNow-technici voeren de reparatiewerkzaamheden uit in onze werkplaats, waar je gewoon meekijkt. Bij ons gebeurt niets achter de schermen. Uniek zijn onze originele schermreparaties, waarop je levenslange garantie krijgt. Wij zijn de eerste in Nederland die deze garantie geven!